When comparing flatbed and sheet-feed scanning, you’ll find flatbeds excel in high-resolution, detailed scans, ideal for fragile or oversized documents, while sheet-feeds provide faster, automated processing for large batches. Flatbeds offer better image quality and precision, but may be slower. Sheet-feeds are more efficient for quick, repetitive tasks but often compromise some quality. To choose the best option for your workflow and document needs, keep exploring the key differences below.

Key Takeaways

- Flatbed scanners excel in high-resolution, detailed scans for fragile or delicate documents, while sheet-feed scanners prioritize speed and high-volume processing.

- Flatbeds offer superior image quality and color accuracy, ideal for photo and artwork scans, whereas sheet-feeds are more efficient for bulk document digitization.

- Flatbed scanners have longer setup times but require less maintenance, while sheet-feed models enable faster batch scanning with more regular cleaning needs.

- Flatbeds are better suited for occasional, high-quality scans, whereas sheet-feeds are optimal for continuous, automated large-volume tasks.

- User interface and ergonomic features are typically more straightforward in flatbed scanners, while sheet-feeds focus on automation and speed.

Overview of Flatbed and Sheet-Feed Scanning Technologies

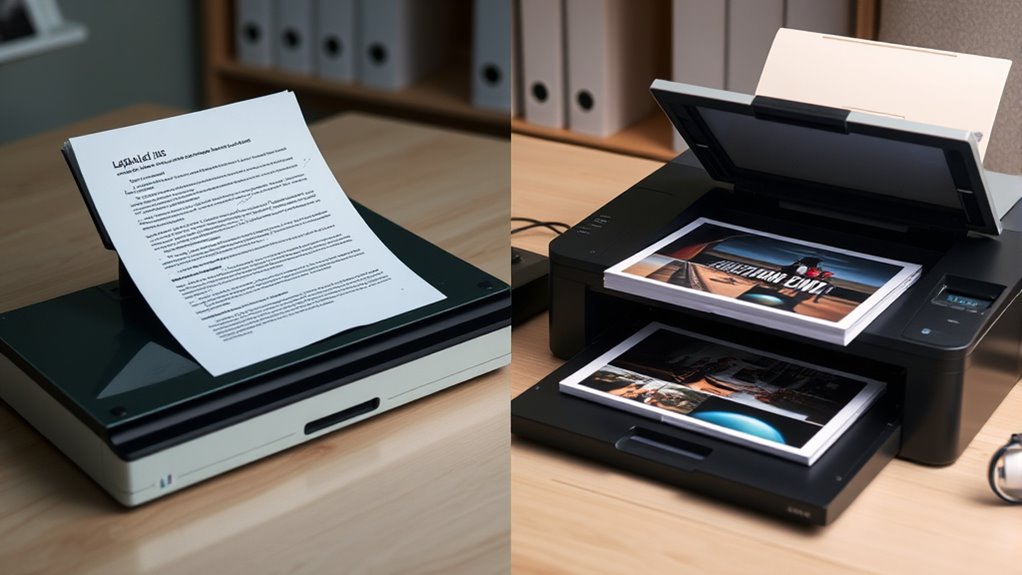

While both flatbed and sheet-feed scanners serve the purpose of digitizing documents, they operate using different mechanisms that suit various needs. Flatbed scanners feature a glass surface where you place each document, making them ideal for delicate or fragile items that require careful document preservation. Their ergonomic design allows you to scan thicker or irregularly shaped materials easily. In contrast, sheet-feed scanners use a feeder tray to automatically process multiple pages quickly, enhancing efficiency for high-volume tasks. Flatbed scanners generally offer higher resolution and better image quality, which is essential for preserving detailed documents. Both types are built to guarantee durability and consistent performance, but their designs reflect distinct priorities: flatbeds focus on precision and preservation, while sheet-feeds emphasize speed and automation.

Design and Construction Differences

The design and construction of flatbed and sheet-feed scanners reflect their distinct functions. Flatbed scanners feature a large, stable glass surface supported by robust mechanical components, allowing you to place various-sized documents comfortably. Their ergonomic design emphasizes ease of use with accessible controls and straightforward access to mechanical parts for maintenance. In contrast, sheet-feed scanners are built with compact, streamlined bodies optimized for rapid document handling. Their mechanical components include advanced rollers and belts that facilitate quick feeding of multiple pages, reducing manual effort. The ergonomic design of sheet-feed models prioritizes user convenience with minimal physical strain during continuous scanning. Overall, the construction differences align with each scanner’s purpose, balancing durability, ease of operation, and efficiency for different workflows.

Speed and Efficiency in Document Processing

When it comes to processing documents quickly, the scanning speed can vary considerably between flatbed and sheet-feed scanners. Batch processing is easier and faster with sheet-feed models, saving you time on large jobs, while flatbeds often require more setup time. Understanding these differences helps you choose the right scanner to maximize your efficiency. Additionally, the choice of eye patch benefits can influence your overall appearance and comfort, especially during long or demanding tasks.

Scanning Speed Variability

Scanning speed can vary markedly between flatbed and sheet-feed scanners, impacting your overall document processing efficiency. Flatbed scanners often have variable speed, especially when scanning thicker or uneven documents, leading to consistency fluctuations. This variability can slow down your workflow, as you may need to pause or adjust settings frequently. In contrast, sheet-feed scanners generally maintain a steadier, more dependable speed, allowing for faster, more predictable scanning sessions. However, their speed may still fluctuate with different document types or sizes. Understanding these differences helps you optimize your scanning process. If speed stability is vital, sheet-feed scanners might serve you better, but if scanning irregular documents, be prepared for some variability that could affect productivity. Additionally, wall organization solutions can help streamline your workspace, indirectly supporting a more efficient scanning environment.

Batch Processing Capabilities

Batch processing capabilities considerably influence your overall document scanning efficiency, especially when handling large volumes. Sheet-feed scanners excel here, offering faster throughput and reduced manual intervention, which boosts productivity. However, this speed can sometimes compromise document durability if not handled carefully, and maintenance requirements tend to be higher due to paper jams and wear. Flatbed scanners, while slower, excel at delicate or fragile documents, minimizing damage and reducing maintenance needs. Proper maintenance practices are essential to sustain efficiency and extend the lifespan of the scanning equipment.

Time for Setup

While sheet-feed scanners typically require more time to set up due to paper alignment and feeding adjustments, flatbed scanners are generally quicker to prepare since you just place the document on the glass surface. This makes flatbeds more efficient when processing small batches or single pages, saving you time upfront. Ergonomics considerations also play a role—flatbeds allow for easier handling, reducing strain during setup. In contrast, sheet-feed scanners may need frequent maintenance, such as clearing paper jams or cleaning rollers, which can slow down your workflow. Overall, flatbed scanners offer faster initial setup, making them more suitable when speed and ease of use are priorities. Their simpler setup process enhances efficiency, especially in environments requiring quick turnarounds. Additionally, security vulnerabilities associated with new scanning technologies highlight the importance of choosing reliable equipment to protect sensitive documents.

Image Quality and Resolution Capabilities

When comparing flatbed and sheet-feed scanners, their image quality and resolution capabilities often stand out as key factors. Flatbed scanners typically offer higher resolution depth, capturing finer details and producing sharper images, which is ideal for high-quality photo or artwork scans. They also tend to provide better color accuracy, ensuring your images reflect true-to-life hues. Sheet-feed scanners, on the other hand, generally prioritize speed over resolution, making them suitable for bulk document scanning but with somewhat lower image detail. If maintaining color fidelity and capturing intricate details matter most, a flatbed scanner might be your best choice. Moreover, the contrast ratio of a scanner influences how well it renders details in dark and bright areas, impacting overall image quality. However, for quick, large-volume scans where resolution depth is less critical, a sheet-feed scanner can deliver acceptable quality efficiently.

Types of Documents Suitable for Each Method

Flatbed scanners excel at handling fragile, oversized, or delicate documents that require careful placement and minimal movement, such as photographs, artwork, or antique papers. They are ideal for items needing gentle document handling and high detail. Sheet-feed scanners, on the other hand, are better suited for high-volume tasks involving standard-sized documents like forms, invoices, or reports, where speed matters. However, compatibility issues can arise depending on document types and scanner features. Additionally, remote hackathons often rely on digital document sharing, making the quality and compatibility of scanned documents important for virtual collaboration.

Cost Considerations and Budgeting

Cost considerations and budgeting play a crucial role in choosing between flatbed and sheet‑feed scanners, as each option varies considerably in initial investment and ongoing expenses. Flatbed scanners often have higher upfront costs but can be more versatile for diverse documents, while sheet‑feed models tend to be more affordable options for high-volume scanning. When planning your budget, consider not only the purchase price but also maintenance, replacement parts, and potential upgrades. Sheet‑feed scanners may save money over time if you process large batches regularly, but flatbeds might be more cost-effective for occasional use. Proper budget planning helps you balance affordability with your scanning needs, ensuring you select a solution that offers the best value without overspending.

Ease of Use and User Experience

Choosing the right scanner involves considering how easy it is to operate and how smoothly it fits into your workflow. A user interface that’s intuitive makes scanning quicker and less frustrating. Look for ergonomic design features, like easy-to-reach buttons and adjustable stands, which reduce fatigue during extended use. Flatbed scanners often offer straightforward operation, while sheet-feed models can streamline batch scanning once you’re familiar with their controls. Consider these aspects to improve your experience:

Choose a scanner with intuitive controls and ergonomic features for a more comfortable, efficient scanning experience.

- Clear, simple menu options on the control panel

- Responsive touchscreens or physical buttons

- Adjustable height and tilt for ergonomic comfort

- Minimal setup steps for quick start

- Visual indicators for status and errors

- Diverse design options can enhance the overall usability by matching your workspace and personal preferences.

Prioritizing ease of use guarantees seamless scanning, saving you time and effort.

Selecting the Right Scanner for Your Needs

Selecting the right scanner depends on understanding your specific needs and workflow. Consider whether color accuracy is essential for your projects or if high-volume speed matters most. Maintenance requirements also influence your decision—flatbeds typically need less frequent upkeep, while sheet-feeds may require regular cleaning. To help, examine this comparison:

| Feature | Best For |

|---|---|

| Color accuracy | Photo editing, archival work |

| Speed and volume | Large document batches |

| Ease of use | Office environments |

| Maintenance needs | Low-maintenance options |

| Document size | Oversized vs standard documents |

Matching these factors with your priorities ensures you choose a scanner that improves efficiency and results. Additionally, understanding the importance of tableware in social and professional settings can help inform decisions about presentation and organization in your workspace.

Frequently Asked Questions

How Do Maintenance Requirements Differ Between Flatbed and Sheet-Feed Scanners?

You’ll find maintenance varies between flatbed and sheet-feed scanners. Flatbeds often need regular cleaning routines to remove dust and smudges from the glass, plus calibration procedures to ensure accurate scans. Sheet-feed scanners require frequent cleaning of rollers and sensors to prevent jams and maintain performance. Both types benefit from scheduled maintenance, but flatbeds focus more on glass cleaning, while sheet-feeds emphasize roller and sensor upkeep.

Can Flatbed and Sheet-Feed Scanners Handle Fragile or Delicate Documents?

You might think both scanners handle fragile documents well, but their handling techniques differ. Flatbed scanners are better for document preservation since you place delicate items gently on the glass, minimizing damage. Sheet-feed scanners can be riskier because they pull documents through quickly, possibly causing tears. If preserving delicate or fragile documents matters most, choose a flatbed scanner for careful handling and better protection during digitization.

What Are the Environmental Impacts of Operating Each Scanner Type?

When considering the environmental impacts of operating scanners, you should focus on energy efficiency and material sustainability. Flatbed scanners generally use less energy and have a smaller carbon footprint, making them more eco-friendly over time. Sheet-feed scanners often require more power due to their faster processing, but they can be more material-efficient with less waste. Choosing an energy-efficient model and sustainable materials helps minimize your environmental impact regardless of the scanner type.

How Do Connectivity Options Vary Between Flatbed and Sheet-Feed Models?

Imagine connecting your scanner effortlessly; your options vary. Flatbed models often feature wireless connectivity, allowing you to scan from anywhere within your network, and they typically support USB compatibility for direct, reliable connections. Sheet-feed scanners usually prioritize fast, wired connections with USB compatibility, but some models now include wireless options. Your choice depends on whether you prefer flexibility or a straightforward, wired setup, making your scanning process smoother.

Are There Specific Industry Standards or Certifications for Each Scanner Type?

You should know that industry compliance and certification standards vary for flatbed and sheet-feed scanners. Flatbed scanners often meet standards like ISO 19264 for image quality, while sheet-feed models may adhere to specific certifications for high-volume scanning, such as UL or CE marks. These standards guarantee your scanner’s reliability, safety, and performance. Always check the manufacturer’s documentation to confirm that your chosen scanner aligns with applicable certification standards for your industry.

Conclusion

Choosing between flatbed and sheet-feed scanners is like picking the right tool for a job. Think of flatbeds as your trusty, detailed paintbrush, perfect for high-quality images and delicate documents. Sheet-feeds are your rapid-fire pen, ideal for quick, bulk scans. Assess your needs carefully, and you’ll find the perfect match—turning your scanning tasks from a cluttered attic into a streamlined, well-organized workspace.